Our client approached Hale Engineering with a pressing need: an automated solution to manage their tank-filling process with precision and without the constant worry of overfilling. This was no ordinary challenge—it demanded a bespoke solution that could blend technical ingenuity with operational simplicity, ensuring flawless performance every time.

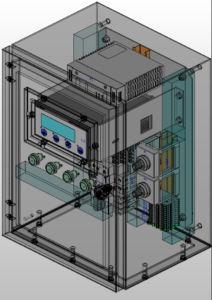

At Hale Engineering, we designed and delivered a compact control panel that transformed their tank-filling operations. This bespoke system not only operates the pump unit but also monitors and adjusts the filling process dynamically for maximum accuracy and safety.

Here’s how it works:

The control panel allows the client to pre-set the desired fluid volume in litres. With a simple press of a button, the pump kicks into action, filling the tank at full speed. When the fluid level reaches 80%, the system automatically reduces the pump speed, ensuring a controlled and safe fill as it approaches capacity. Finally, once the tank reaches 100%, the filling process stops automatically, removing any chance of overfilling.

For added flexibility, the system also includes a manual override, enabling the client to halt the process at any point if needed.

The Results

The new system has delivered immediate and tangible benefits:

- Improved Efficiency: The fully automated process freed up the client’s staff from the time-consuming task of manual monitoring.

- Precision and Control: The dynamic speed adjustment and automatic stop feature ensured that the exact fluid volume was delivered, every time.

- Enhanced Usability: The intuitive interface made it simple and straightforward to use, integrating seamlessly into their workflow.

This innovative solution didn’t just solve their problem; it redefined how they approach tank-filling operations. The client now enjoys peace of mind, knowing their system works reliably in the background without constant supervision.

For enquiries or to learn more about our services, contact Hale Engineering directly at:

Phone: +44 20 8154 6102

Email: info@hale-eng.co.uk