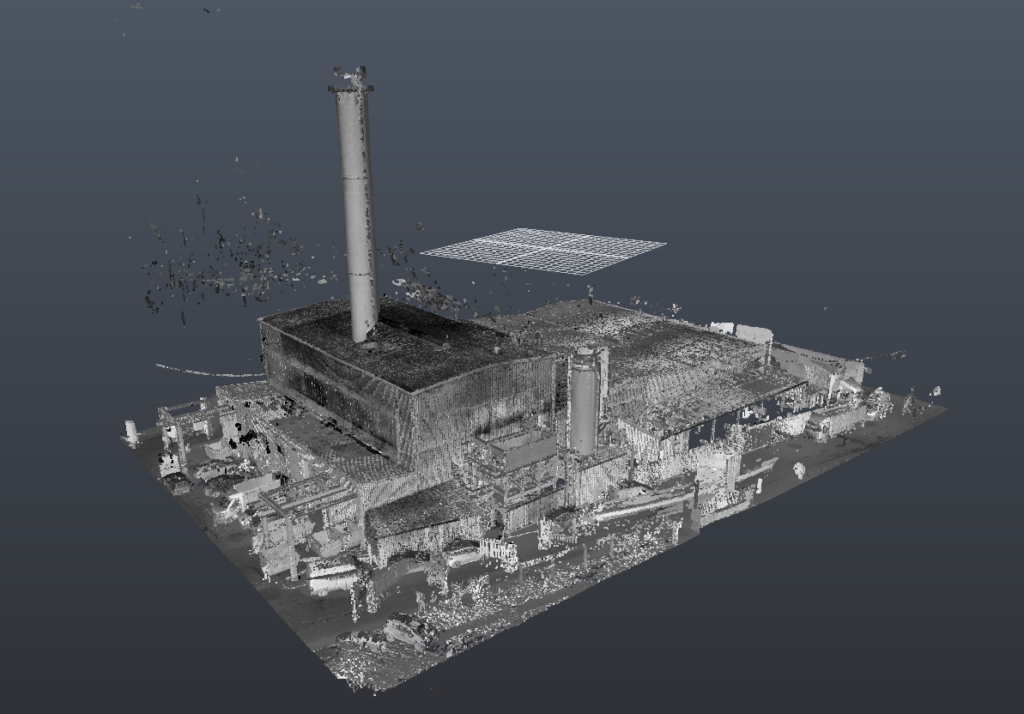

Hale Engineering has undertaken a new project where we are using laser scanning technology to design a replacement control system for an industrial plant. By creating a highly accurate 3D model of the client’s site, we ensure precision in the integration of the new system. This approach enhances efficiency, reduces downtime, and eliminates errors, resulting in a seamless and optimised control system design.

Hale Engineering’s Approach

Harnessing the power of laser scanning, we capture precise 3D data of the plant with millimetre accuracy. This data is then transformed into a detailed digital model, serving as the foundation for designing the new control system.

Harnessing the power of laser scanning, we capture precise 3D data of the plant with millimetre accuracy. This data is then transformed into a detailed digital model, serving as the foundation for designing the new control system.

Our expertise in automation and control system design ensures that the new system fits seamlessly into the existing plant layout.

Why Choose Hale Engineering?

Our deep understanding of industrial automation, combined with cutting-edge laser scanning technology, allows us to provide unparalleled accuracy, efficiency, and cost savings.

Here’s how our approach benefits our clients:

1. Unmatched Accuracy & Precision

1. Unmatched Accuracy & Precision

Our laser scanning technology captures millimetre-accurate measurements, ensuring every control system component integrates seamlessly into the existing plant layout.

2. Faster & Smarter Data Collection

Unlike traditional manual methods, our approach rapidly gathers vast amounts of critical data, reducing site downtime and project delays.

3. Intelligent Design Optimisation

Our 3D models allow engineers to visualise and simulate control system installations before implementation, identifying potential clashes early in the process.

4. Cost-Effective Solutions

By detecting space constraints and interferences before installation, we minimise costly revisions, rework, and project delays.

5. Safer Working Conditions

Our expertise in laser scanning eliminates the need for manual measurements in hazardous areas, significantly improving on-site safety.

6. Seamless CAD/BIM Integration

We integrate scan data directly into CAD and BIM platforms, enabling smooth collaboration between engineering teams and reducing design bottlenecks.

7. Future-Proof Documentation

The detailed 3D model we provide serves as an invaluable reference for future upgrades, maintenance, and troubleshooting.

8. Remote Collaboration & Efficiency

Our cloud-based data sharing enables stakeholders to review and collaborate remotely, reducing the need for multiple site visits and accelerating project timelines.

The Results

Through our expertise and cutting-edge technology, Hale Engineering is developing a highly accurate and optimised design for the new control system. Our precision-driven approach is reducing project risks and costs while enhancing safety, efficiency, and long-term operational reliability for our client. The 3D model we provide will serve as a vital asset for future expansions and maintenance.

Through our expertise and cutting-edge technology, Hale Engineering is developing a highly accurate and optimised design for the new control system. Our precision-driven approach is reducing project risks and costs while enhancing safety, efficiency, and long-term operational reliability for our client. The 3D model we provide will serve as a vital asset for future expansions and maintenance.

At Hale Engineering, we are committed to setting new industry standards by leveraging state-of-the-art technology. Our expertise in laser scanning ensures precision, efficiency, and cost-effectiveness in every project we undertake. By embracing innovative solutions, we help clients future-proof their operations and achieve operational excellence.

If you’re looking for a trusted partner to optimise your industrial automation projects, Hale Engineering has the expertise and technology to deliver superior results.

For enquiries or to learn more about our services, contact Hale Engineering directly at:

Phone: +44 20 8154 6102

Email: info@hale-eng.co.uk