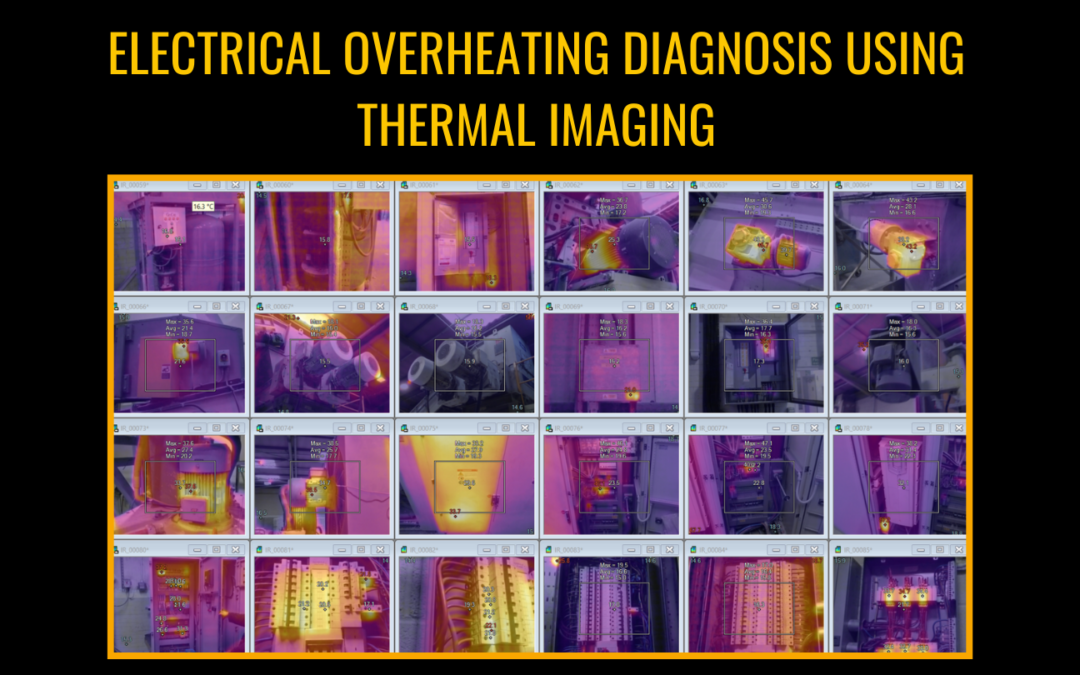

| Thermal imaging has become an essential tool in diagnosing electrical overheating, offering a non-invasive way to ensure safety, efficiency, and equipment reliability. By detecting heat emitted from electrical components, thermal imaging allows engineers to identify potential issues before they escalate into costly repairs or safety hazards. |

Our client, an industrial facility, was experiencing recurring electrical failures due to overheating in its systems. Routine inspections failed to identify the root cause, and the facility was facing unexpected downtime and increased repair costs.

Our client, an industrial facility, was experiencing recurring electrical failures due to overheating in its systems. Routine inspections failed to identify the root cause, and the facility was facing unexpected downtime and increased repair costs.

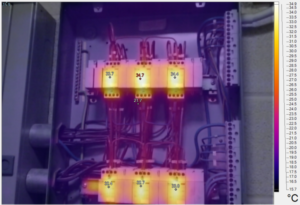

Our engineers conducted a thermal imaging survey to assess the situation. Using advanced infrared cameras, we scanned the electrical systems to detect hotspots invisible to the naked eye. The thermal map revealed several areas of concern, including loose connections, overloaded circuits, and damaged insulation, all of which contributed to excessive heat generation.

Here is how thermal imaging improved operations

By identifying these problem areas early, our team was able to address the issues without disrupting operations. The results were immediate:

- Reduction in electrical failures: Equipment performance stabilised, and the facility experienced fewer breakdowns.

- Cost savings: Preventive maintenance and targeted repairs led to significant savings within the first year.

- Improved safety: By reducing the risk of electrical fires, the facility achieved a safer working environment.

- Extended equipment lifespan: Proactive maintenance extended the life of critical equipment, avoiding costly replacements.

Why thermal imaging?

Thermal imaging uses infrared cameras to detect heat emitted from electrical components. These cameras capture temperature differences that are invisible to the naked eye, producing a color-coded image (thermal map).

Thermal imaging uses infrared cameras to detect heat emitted from electrical components. These cameras capture temperature differences that are invisible to the naked eye, producing a color-coded image (thermal map).

Thermal imaging stands out as a powerful diagnostic tool for several reasons:

- Non-disruptive: Allows for real-time monitoring without the need to shut down systems.

- Accurate detection: Identifies hidden issues, ensuring early intervention.

- Cost-effective: Prevents costly repairs and reduces downtime.

- Enhanced safety: Significantly lowers the risk of electrical fires.

All our engineers are fully trained to complete thermal imaging surveys.

If your facility is facing electrical issues or you want to ensure proactive maintenance, our trained engineers can help. We specialise in thermal imaging surveys and electrical diagnostics to safeguard your operations and prevent costly breakdowns.

Contact us today to schedule a thermal imaging survey or to learn more about our consultancy services.

Phone: +44 20 8154 6102

Email: info@hale-eng.co.uk

Website: www.hale-eng.co.uk