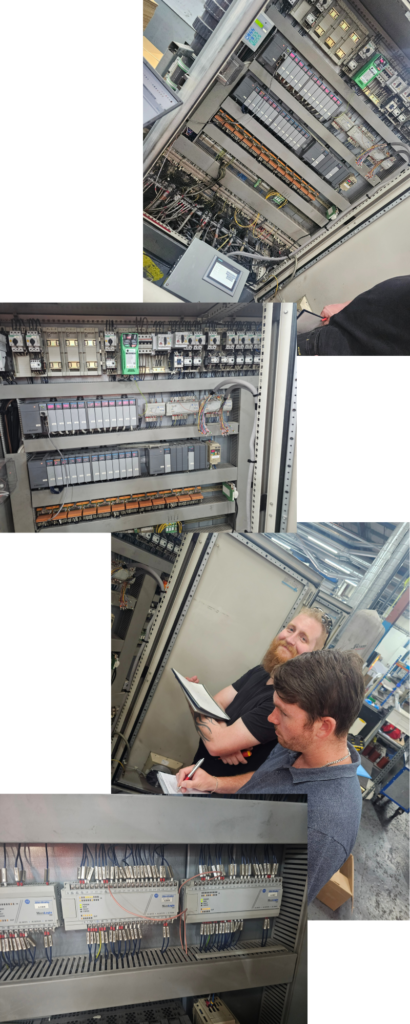

Our case study unveils a PLC upgrade solution for a prominent industrial client. The challenge was an Allen Bradley system that was locked off, making conventional coding export impossible. This scenario is all too common, with outdated control hardware often anchoring various industrial installations.

Obsolete, Unsupported Hardware: A Growing Concern for Industries

The lifecycle of controls hardware is often limited, with OEMs supporting past generations for a set period. As hardware becomes outdated and unsupported, the hunt for replacement parts gets increasingly challenging and expensive. Consequently, industrial facilities become susceptible to sudden, prolonged downtime should a breakdown occur.

Introducing a Revolutionary Solution: Portable PLC for Seamless Control System Upgrades

Our controls team’s significant strides led to the creation of a portable PLC capable of studying existing control systems on the go. This groundbreaking solution leverages modern Siemens hardware and software, establishing seamless connectivity with the I/Os and efficiently logging the old PLC’s activity.

The Importance of Logged Data in Reverse Engineering

The logged data serves as a goldmine for understanding and reverse engineering the legacy code. Our team, by analyzing the data, can glean valuable insights into the existing system’s functionality and behavior. It empowers us to replicate the coding accurately and develop a compatible version that fits the bill for the latest hardware.

The benefits of this development are manifold, beginning with the elimination of a complicated, time-consuming reverse engineering process. Instead, we can utilize the logged data to recreate the control logic efficiently and implement it on upgraded hardware.

Why Should You Consider Upgrading Your Control Systems?

Cost Savings:

Upgrading from an outdated control system reduces the risk of unexpected breakdowns and complete replacement needs. It also cuts down downtime, maintenance expenses, and production disruptions. Moreover, contemporary control systems generally are more energy-efficient, which can mean significant savings on utility bills.

Efficiency Boost:

Outdated systems often lag in efficiency compared to modern systems. An upgrade helps leverage cutting-edge technology to optimize processes, minimize waste, and ramp up productivity.

Enhanced Capabilities:

New-age control systems come packed with advanced features not found in older generations. They provide better communication, integration options, improved situational awareness, and process overview.

Scalability:

If your production plans involve expansion, an upgraded control system becomes essential. It can manage additional production lines effectively, allowing seamless scale-up sans outdated technology constraints.

Ease of Repair & Replacement:

With widely available knowledge and components, maintaining, repairing, and updating modern control systems is a breeze. Upgrading minimizes downtime and eliminates the need for complicated reverse engineering.

Simplicity & User-friendliness:

User-friendly interfaces and efficient automation features make modern control systems a breeze to operate. This reduces the likelihood of operator errors, improving product quality, knowledge transfer, and overall efficiency.

In conclusion, the obsolescence of control hardware poses a significant challenge to industries, yet it also opens doors to improvements and advancements. Our innovative approach to PLC reverse engineering and upgrade, demonstrated in this case study, underscores the transformative potential of modern control systems.

Not only does our portable PLC solution streamline the upgrade process, it also makes way for numerous benefits: cost savings, increased efficiency, enhanced capabilities, scalability, and user-friendliness. It demonstrates that a systematic, data-driven approach can alleviate the risks associated with outdated hardware, and preparing for the future where sudden downtimes and system inefficiencies are a thing of the past.