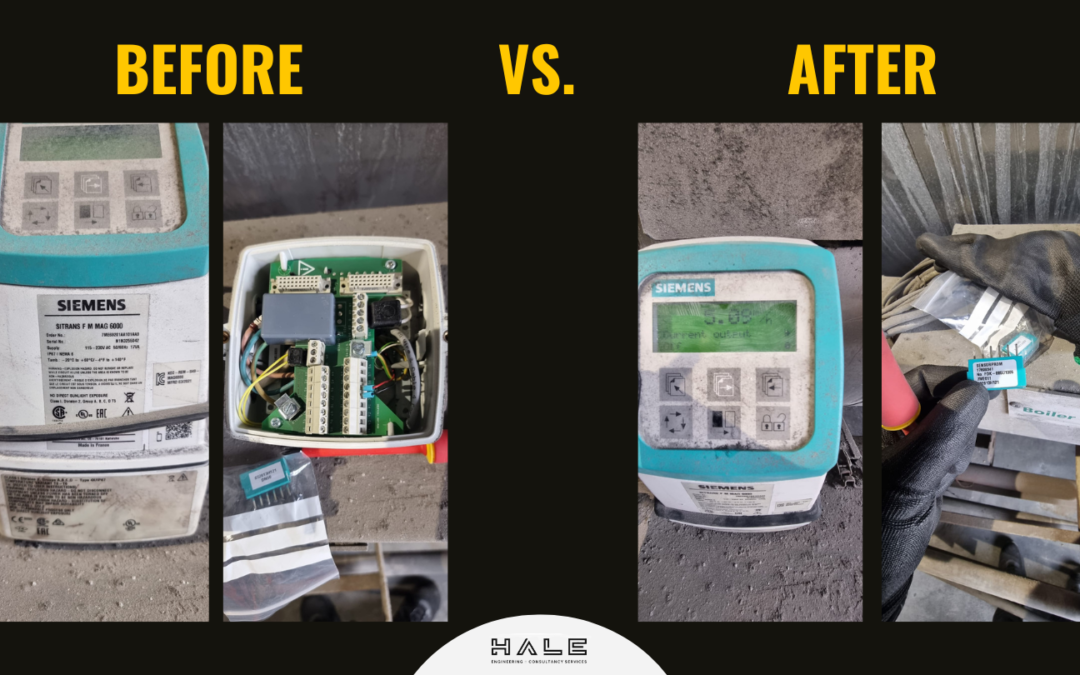

Here we have a short case study by Hale Engineering. Sean commissioned a Siemens MAG 5000 flow meter, designed to monitor the m³/h steam flow from a boiler.

Here we have a short case study by Hale Engineering. Sean commissioned a Siemens MAG 5000 flow meter, designed to monitor the m³/h steam flow from a boiler.

He configured the 4-20 mA output to an Allan Bradley controller, enabling real-time data transmission and control. The value was then monitored by a SCADA system.

This system captures and records the flow meter’s readings at hourly intervals. Sean followed the Siemens flow meter calibrations fitted to the transmitter to ensure correct flow values.

See the step by step process in the pictures and videos embedded.

Here’s one of our tiktoks to showcase our case study!!…