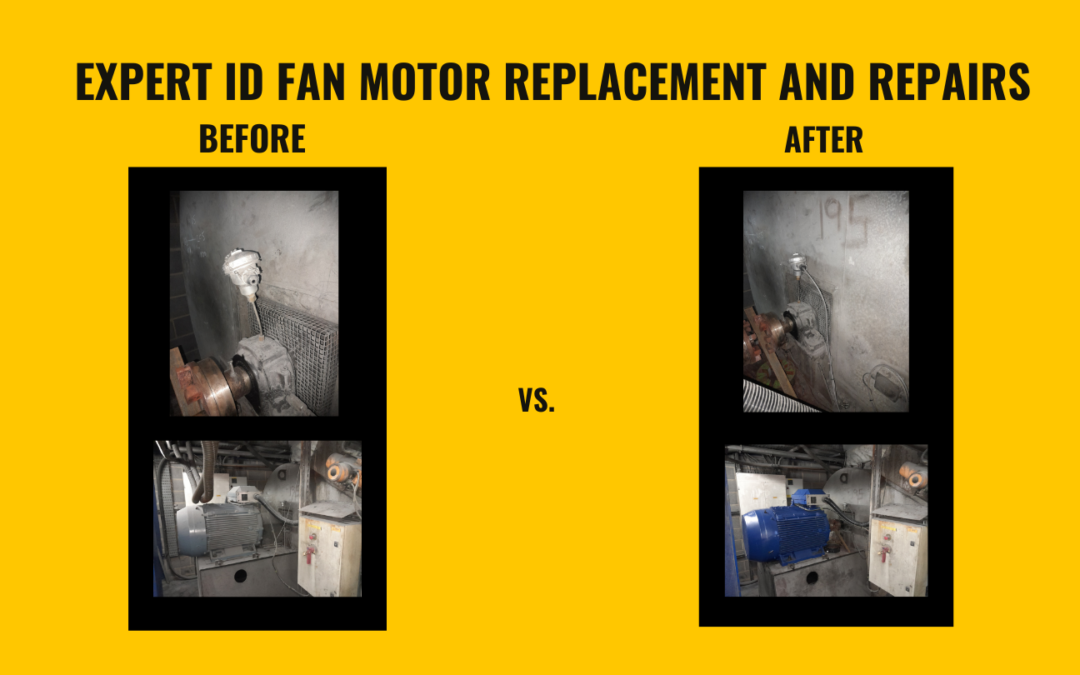

When it comes to critical components like ID (Induced Draft) Fan motors, ensuring seamless replacement and addressing associated issues is crucial to avoid costly downtime. In this article, we delve into a recent success story involving Hale Engineering, where their team member was dispatched to perform the disconnection of an old ID Fan motor and the subsequent installation of a new one. Along the way, they also addressed a damaged bearing Temperature Probe cable, ensuring a fully functional system.

The Challenge

When the old ID Fan motor at the site started showing signs of wear and reduced efficiency, the client contacted Hale Engineering to tackle the issue promptly. Understanding the urgency, a Hale Engineering team member was swiftly dispatched to the site to assess the situation and take necessary action.

The Solution

The engineer approached the task methodically, adhering to industry best practices. The process unfolded in the following stages:

Isolation and Disconnection of Old ID Fan Motor:

The first step was to isolate and disconnect the old ID Fan motor. This was done with precision to ensure the safety of both the engineer and the equipment. Isolation is crucial to prevent any unintended electrical connections during the replacement process.

Installation of the New ID Fan Motor

With the old motor out of the way, the new ID Fan motor was installed. This phase demands precision and expertise to ensure that the motor is securely mounted, aligned, and ready for operation.

Connection to Electricity Source

Once the new motor was in place, the engineer proceeded to connect it to the electricity source. This is a delicate operation, as it requires accurate wiring to ensure the motor receives the correct voltage and current for optimal performance.

Addressing a Damaged Bearing Temperature Probe Cable

During the replacement process, the engineer identified a damaged bearing Temperature Probe cable. Recognising the importance of this component for monitoring and maintaining the motor’s temperature, the engineer promptly replaced the damaged cable and ensured that it was functioning correctly.

Success and Benefits

The efforts of the Hale Engineering team member paid off as the temperature probe test passed successfully. This meant that the newly installed ID Fan motor was operating within the desired temperature range, ensuring the efficient performance of the entire system.

The successful replacement of the ID Fan motor not only averted potential downtime but also improved the overall efficiency and reliability of the industrial process. The client was delighted with the results, as they could continue their operations with confidence, knowing that their critical machinery was in optimal condition.

In conclusion, the case of Hale Engineering’s successful ID Fan motor replacement and repairs highlights the importance of timely and expert maintenance in the industrial sector. With attention to detail, a focus on safety, and a commitment to addressing all potential issues, Hale Engineering exemplifies the qualities of a reliable and efficient service provider in the field of industrial engineering.