This case study highlights the upgrade of our Roof Fan Control circuits, where we detail the essential steps, from initial planning to panel construction.

This case study highlights the upgrade of our Roof Fan Control circuits, where we detail the essential steps, from initial planning to panel construction.

Planning for Success: The case study began with a site visit by our engineer, gathering crucial data to shape the project’s direction. This information laid the foundation for a comprehensive plan, encompassing panel replacement, new supply circuit installation, and the removal of redundant components and circuits.

Generating a Parts List: With the plan in hand, our next task was to create a parts list. This list was submitted to our Operations Manager, accompanied by a circuit diagram that integrated the new components, all in preparation for the construction of the new panel.

Ordering and Building: We then took immediate action. The first task involved removing the old control panel on the ground floor and connecting existing fan supply cables. Then we ran and connected four new fan supply cables from the freshly minted ground floor control panel to fans that had previously drawn power from a panel at the top of the Baghouse.

Ordering and Building: We then took immediate action. The first task involved removing the old control panel on the ground floor and connecting existing fan supply cables. Then we ran and connected four new fan supply cables from the freshly minted ground floor control panel to fans that had previously drawn power from a panel at the top of the Baghouse.

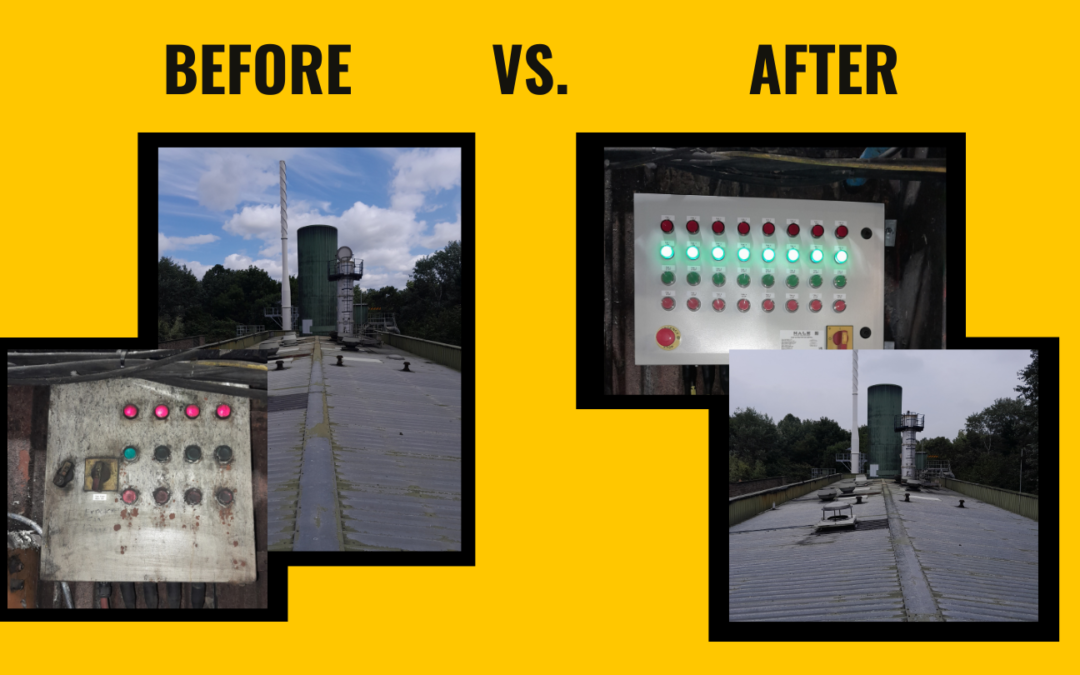

In our pursuit of precision, we swapped out isolator switches and established new cable terminations for all extractor fans. Furthermore, we addressed cable containment, adding a new one for cables supplying fans 1, 2, 3, 4, 7, and 8, while fans 5 and 6 found a new home in an existing containment run. Finally we got of all the redundant cabling and components that once cluttered the top of the Baghouse. You can see the before and after photos embedded within this page to get a visual idea of what we were implementing.