Often in engineering, the need to upgrade and integrate with legacy control systems is a common challenge. This case study delves into a scenario where our client’s existing Mitsubishi PLC lacked the capability to communicate with an advanced SNCR system. These systems are being increasingly used to effectively reduce harmful emissions during combustion. This communication gap issue required a strategic solution which our team carefully implemented.

The Challenge

The on-site client had utilised an older version of a Mitsubishi PLC, which, unfortunately, had limitations in terms of adding more inputs and outputs. So, the client expressed a crucial need for the integration of the SNCR system into their operations. This presented a significant hurdle, as the existing Mitsubishi PLC was unable to communicate directly with the SNCR system.

Solution Implemented By The Hale Engineering Team

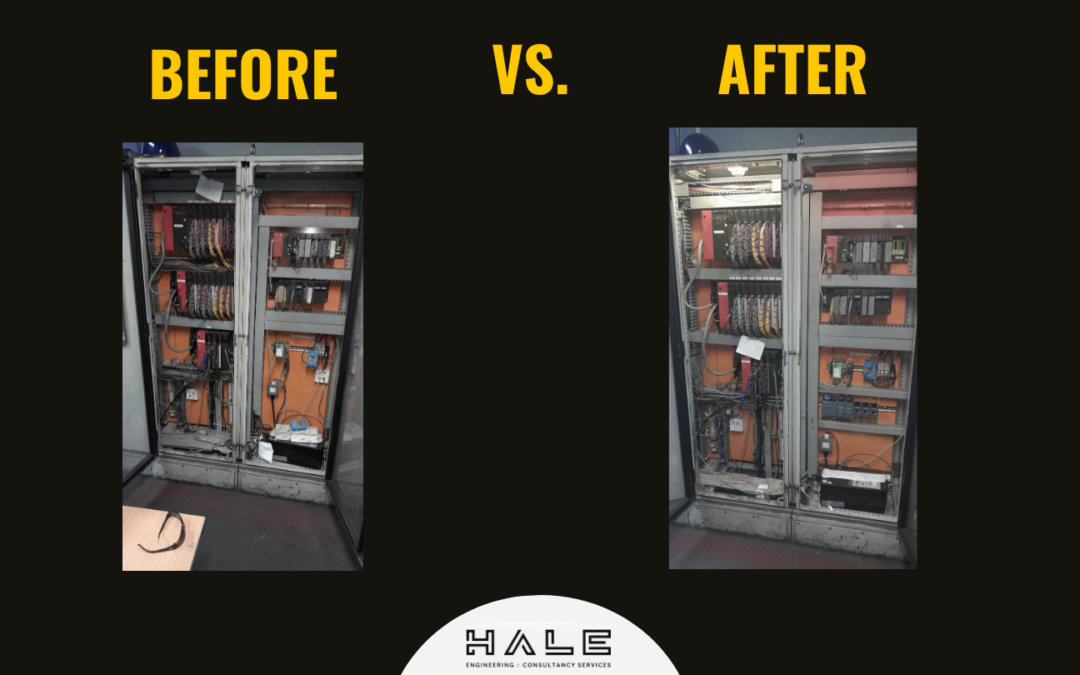

To address this communication gap, our team proposed and implemented a solution involving the installation of a new Siemens PLC. This Siemens PLC served as an intermediary, facilitating seamless communication between the SNCR system and the legacy Mitsubishi PLC.

Key Components of the Solution

- Siemens PLC Integration: The Siemens PLC was strategically introduced to act as a bridge between the SNCR system and the old Mitsubishi PLC. Its advanced capabilities allowed for the incorporation of additional inputs and outputs, overcoming the limitations posed by the legacy Mitsubishi PLC.

- Analog Signal Processing: The Siemens PLC was configured to receive analog signals from the SNCR system. These signals provided essential feedback, enabling the Siemens PLC to process the data effectively.

- Data Transfer to Mitsubishi PLC: Once processed, the Siemens PLC seamlessly transferred the data to the Mitsubishi PLC. This step was crucial, as the Mitsubishi PLC lacked the inherent capability to directly communicate with the SNCR system.

Outcome and System Functionality

The integration of the Siemens PLC successfully facilitated the incorporation of the SNCR system into the existing setup. The analog inputs from the SNCR system were efficiently processed by the Siemens PLC, and the resulting data was communicated to the legacy Mitsubishi PLC.

This successful case study highlights the importance of innovative solutions in the face of industrial automation challenges. The strategic integration of a Siemens PLC effectively bridged the communication gap between the SNCR system and the outdated Mitsubishi PLC, ensuring the continued and enhanced functionality of the SNCR system.