Here are some interesting case studies from the past –

1.Gas Screw Compressor Control System

Our client was manufacturing two gas screw compressors. We designed and built the associated control panels and software, which was based upon a Mitsubishi PLC. Both of the units were shipped to Croatia for install and commissioning.

Our client was manufacturing two gas screw compressors. We designed and built the associated control panels and software, which was based upon a Mitsubishi PLC. Both of the units were shipped to Croatia for install and commissioning.

2.Chemical Dosing

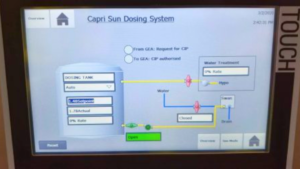

We were requested to design, supply, and install an automated dosing system to control the chlorine level within a tank; the existing system was manual and time-based but, due to expansion, the system had become inadequate.

We were requested to design, supply, and install an automated dosing system to control the chlorine level within a tank; the existing system was manual and time-based but, due to expansion, the system had become inadequate.

The new system was based upon a chlorine monitor with a continuous flow. One issue was that the system would occasionally require a CIP—this would damage the monitoring equipment—so the system we designed would switch over to a fresh water supply and provide a CIP enable.

3.Bolton Incinerator Plant Rewire

Due to extreme environmental conditions, the wiring and associated components of the plant had degraded to the point where a complete rewire of the process was necessary. This included the replacement of a number of outstations, and the replacement of the MCC.

Due to extreme environmental conditions, the wiring and associated components of the plant had degraded to the point where a complete rewire of the process was necessary. This included the replacement of a number of outstations, and the replacement of the MCC.

Also due to the age of the installation, it was necessary to review and replace the safety system, which we replaced with a Pilz programmable unit.

This project was undertaken in 10 weeks with a 4-week shutdown.